Consider printing technology, material options, quality, lead times, cost, and technical support when choosing a 3D printing company.

A lot of businesses have started providing 3D printing services as a result of the technology’s increased affordability and accessibility in recent years. These businesses range in size from big, international conglomerates to tiny, neighborhood 3D printing shops. They provide a broad range of services, including low-volume production, custom manufacturing, product design, and prototyping. Due to the rising demand for 3D printing, companies and individuals seeking high-quality, reasonably priced 3D printing services now have a wide range of options.

8 Factors to Consider When Choosing a 3D printing company?

Selecting the best 3D printing company is crucial for a number of reasons, including lead time, material options, cost-effectiveness, and print quality. You can select the best 3D printing company to suit your needs and help you get the best results for your project by carefully weighing these factors.

Here are a few factors to consider when choosing a 3D printing company:

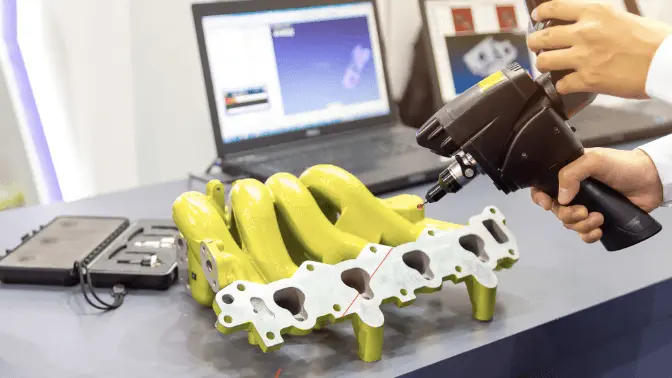

Printing Technology

Different 3D printing companies may use different printing technologies, so consider which technology best suits your project needs.

There are several 3D printing technologies to consider for product design, including:

- Fused Deposition Modeling (FDM): This popular and cost-effective technology uses a thermoplastic material and a hot end to build parts layer by layer. FDM is an excellent choice for low-fidelity prototypes and production jigs

- Stereolithography (SLA): SLA is a process that uses UV light to cure a liquid resin into a solid form, creating highly accurate and detailed parts.

- Selective Laser Sintering (SLS)Selective Laser Sintering: SLS is a process that uses a laser to fuse powdered materials into a solid form, creating strong and durable parts.

- Multi Jet Fusion (MJF): MJF is a process that uses thermal energy and a fusing agent to create parts with high accuracy and resolution.

- PolyJet: This technology uses a process that jets and cures liquid photopolymer into a solid form, creating parts with high accuracy, resolution, and smooth surface finish.

- Direct metal laser sintering (DMLS): This technology uses a high-power laser beam to melt and fuse metal powders to create metal parts with good accuracy and resolution.

The ideal technology for your project will depend on a number of variables, including the amount of material needed, the level of accuracy and resolution required, lead time, cost, and more. Speak with a 3D printing company to find out which technology is best for your product design.

Material Options

Consider the range of materials the company offers and if they can meet your specific material requirements.

There are many different 3D printing materials to choose from, including:

- Plastics – ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), PET (Polyethylene Terephthalate), Nylon, TPU (Thermoplastic Polyurethane), and more.

- Metals – Steel, Titanium, Aluminium, Copper, and Brass

- Resins – Photopolymer resins and epoxy resins

- Speciality materials – Including flexible materials, conductive materials, and magnetic materials

The best material for your project depends on the specific requirements of your product, such as strength, flexibility, thermal resistance, and temperature requirements.

Quality and Accuracy

Quality and accuracy are critical factors when choosing a 3D printing company. These factors can directly impact the end product’s functionality, reliability, and appearance.

Consider the following when evaluating the quality and accuracy of a 3D printing company:

- Equipment – Check if the company uses high-end 3D printing equipment and if they regularly maintain and upgrade their equipment.

- Process control – Ensure the company has established procedures and protocols to ensure consistent quality and accuracy from print to print.

- Quality assurance – Ask about the company’s quality assurance process, including how they inspect and test printed parts for accuracy, durability, and other vital properties.

- Case studies – Look for case studies or reviews from previous customers to get an idea of the company’s track record for delivering high-quality, accurate prints.

- Samples – Request samples to physically inspect the quality and accuracy of their prints.

By considering these factors, you can ensure that you choose a 3D printing company that has the experience and expertise to deliver high-quality, accurate prints that meet your product requirements.

Read Also:Top Benefits Of Learning a New Language

Lead Time

A key consideration when selecting a 3D printing service provider is lead time. The lead time is the amount of time that elapses between placing an order and the delivery of the finished product. The project timeline may be impacted by a lengthy lead time, which could result in delays and increased expenses. Here are some things to think about to see if they can complete your project by the deadline:

- Turnaround time – Ask about the company’s typical turnaround time for a project similar to yours.

- Capacity – Check if the company can handle your project promptly.

- Workload – Consider the company’s current workload and if they have the resources to prioritise your project and meet your timeline.

- Communication – Make sure the company has clear and open lines of communication and that they keep you informed of any changes or potential delays.

- premium options – Ask if the company offers premium options for projects with tight timelines. These are sometimes called Rush options.

Considering these factors, you can choose a 3D printing company with the capability and resources to meet your project timeline and minimise potential delays.

Cost

The size and intricacy of the model, the kind of material used, and the turnaround time all affect how much a 3D printing service will cost. 3D printing can cost anywhere from £10 to several thousand dollars on average. It’s best to get in touch with the business you’re interested in working with and give them the specifics of your project in order to receive an accurate quote.

Cost-effectiveness: The cost of printing can vary significantly based on the type of material, the size of the object, and the required level of detail. Different 3D printing companies have different pricing structures. You can save costs and still obtain the necessary quality by selecting the right provider.

Obtain quotes from several businesses and evaluate their costs, but keep in mind that the least expensive option might not always be the best one.

Customer Service

Verify the customer service department’s responsiveness and helpfulness to make sure you will receive support from them during the printing process.

Technical support

In 3D printing, technical assistance can be very important, particularly if you are just starting out. If you have any questions or concerns, a reputable 3D printing company will have knowledgeable support staff to help you out.

Location

Think about whether working with a local or remote company is more convenient for you, taking into account your location and shipping requirements. You can choose a 3D printing company that best fits your unique needs and requirements by taking these factors into consideration.

There are many 3D printing service companies; here are some of the most well-known ones:

- Shapeways

- Sculpteo

- i.Materialise

- Stratasys Direct Manufacturing

- Xometry

- Proto Labs

- Pinshape

- FDM3D

- 3D Hubs

- MyMiniFactory

These businesses use a variety of technologies, such as FDM, SLA, SLS, and PolyJet, to provide a range of 3D printing services, including low-volume production, on-demand manufacturing, and prototyping.

Share this post on